Description of the product

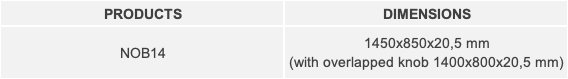

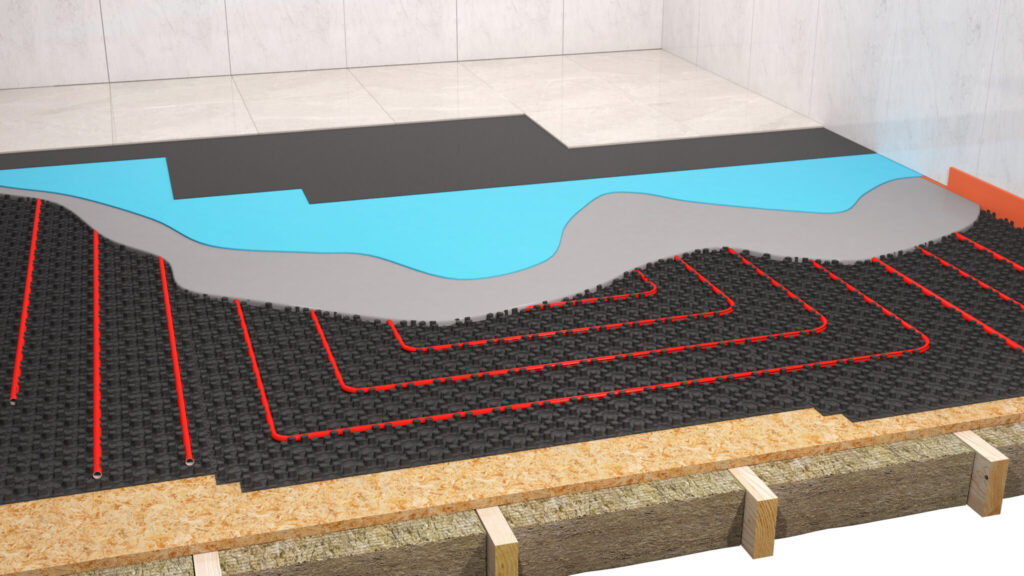

Tycroc NOB panel is nob foil 1 mm thermoformed element for use in wet installation of underfloor heating, with specially designed “nobs”guaranties perfect fi xing of the underfl oor heating pipe. NOB panels will be covered by concrete, gypsum cast or self-leveling . The panel is equippedon two sides with two extra rows of nobs which allowed a keyed and frictional connection preventing penetration of screed into the contruction,based on the high inherent stability the panel is well walk-on-able.

Places of use and panel installation

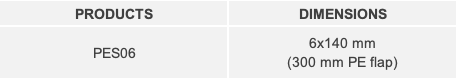

Before proceeding with the installation of the wet installation system, the site conditions must be checked – which must comply with the relative technical standards. Passages of pipes and/or cables must be suitably covered and recessed in the substrate layer in order to guarantee the base surface for laying the NOB panel. Installing Tycroc NOB panel the underlying surface has to be level, dry, strong, rigid and stable. It also has to befree from dirt, oil or other lubricants and it cannot be frozen. If necessary, the underlying surface has to be levelled using products for intended use. Tycroc NOB panel is suitable for installing onto a bearing surface, both onto a wooden structure (for example boarding, OSB board, plywood,etc.) as well as onto a concrete surface. If the substrate does not meet the requirements of DIN 18202, it must be levelled with a suitable product.

Correct system installation involves using Tycroc PES perimetral strip at the fl oor/wall corners of the subfl oor and then installing Tycroc NOB panel directly to the subfl oor. Tycroc NOB panel should be installed with the panels overlapping and the fl oor/wall edges against the Tycroc PES perimetral strip. If there are portions of the subfloor not covered by NOB panels, these must be protected by a PE sheet to prevent the screed from anchoring to the subfl oor itself, ensuring that the screed is in all respects fl oating.

It is recommended to start laying the panels starting from a corner of the room in the direction of the longest wall. Cut the excess part of the last panel of the row with a cutter and inserting the advanced part in the next row, making the joints coincide, so you can phase out the rows ensuring greater compactness and a reduction of scraps.

Laying the perimetral strip

The perimetral strip acts as a perimetral joint. It must be laid along the entire perimeter of the premises to be heated and around all the elements of the structure that penetrate the screed covering the system, such as pillars,stairs, etc. strip of adequate height useful and such as to also include the flooring. Tycroc PES perimetral strip has a thickness of 6 mm and a height of 140 mm, which is cut to size before the finishing material is applied. In addition, there is also self-adhesive edge strip and 300 mm PE flap to cover the edges of the NOB panel.

Pipe laying

Tycroc NOB panel provides multiple steps of 5 cm, the laying of the 14-17 mm pipe must respect the project in terms of the maximum pitch and length of the circuits. After consulting the executive project, it will be necessary to identify the point from which to start and the relative connection to the manifold, so that the pipes at the start and finish have a radial distribution without any overlapping.

Tycroc NOB panel allows the installation pipes at 90° as well as 45°. Possible pipe installation pitches are 50 mm / 100mm / 150 mm / 200 mm for 90° installation and 71 mm / 142 mm / 213 mm / 284 mm for 45° installation.

Laying and finishing

The coverage will take place according to the relative standards and the provisions of the specific categories.

Laying the level must follow the manufacturer’s instructions. Minimum and maximum allowed thikness of the screed must follow the manufacturer’s instructions. The coatings will be laid in a dry screed and after measuring the residual humidity with a special CM carbide meter.

Sometimes, for improve the execution of the floor, it may be required to heat the screed further through the floor system. This is the case, for example, of the laying of glued wooden floors: put for some days in operation, the heating before starting to smooth the floor allows a settling parquet before grouting. For the application of the level, in consideration of the reduced thicknesses and protection of the final system performance, it is recommended to use specialized application teams.

Detailed installation instructions on the page Installation instructions.