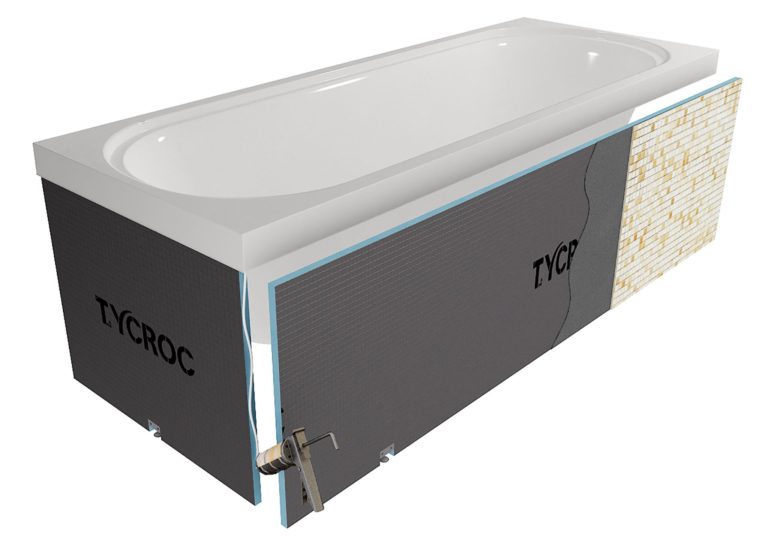

Description of the material

Tycroc bathboard has been made from Tycroc TWP board, with the inner part being extruded polystyrene (XPS foam). To ensure the rigidity and durability of the board, its waterproof foam core is covered with a layer of polymer cement mortar, on top of which there is reinforcing fibreglass mesh followed by another layer of polymer cement mortar. This surface is immediately ready for finishing works.

Characteristics and advantages

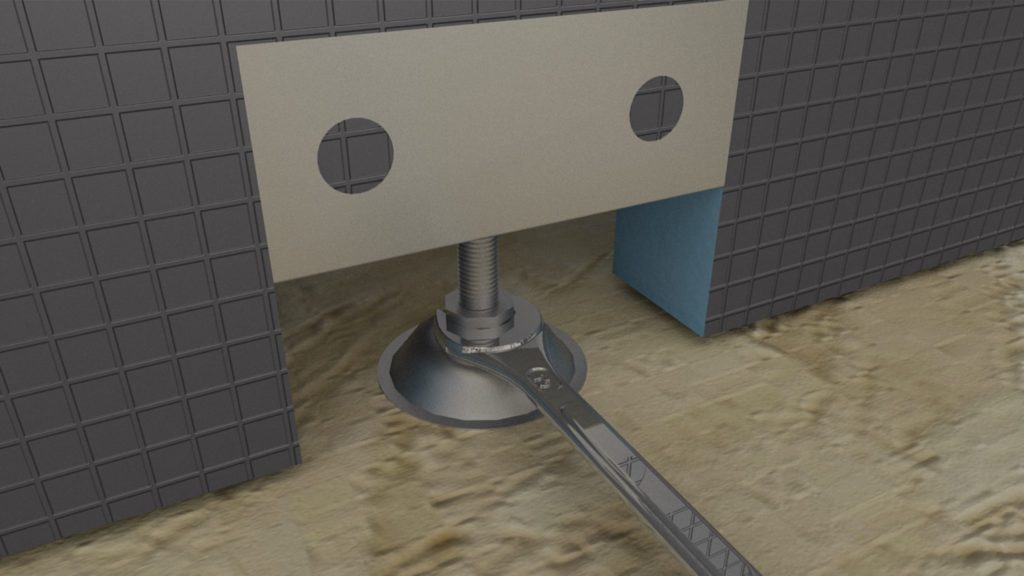

Tycroc bathboard has adjustable metal legs for ease of installation. The bath panel is waterproof, blocking water, i.e. water and humidity cannot penetrate the board. As Tycroc TWP board, the bath panel is lightweight and easily installable as well (the weight of 30 mm board is ca 3.7 kg/m²). Its main advantages, compared to the widely used wet room construction solutions, are ease and speed, as well as the knowledge that the product is a closed-cell one (0 capillarity), i.e. water neither enters the material nor penetrates it. If necessary, inspection openings can be cut into the panel.

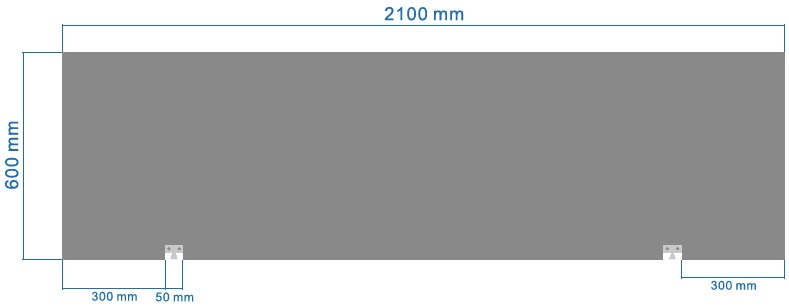

Dimensions: BCS30 – 2100x600x30 mm; BCH30 – 770x600x30 mm

Place of use

Tycroc bathboard is designed to cover the side or end of the bath so that no additional framework is needed.

Detailed installation instructions on the page Installation instructions.